Actuator(Piezoelectric element)

About Actuator

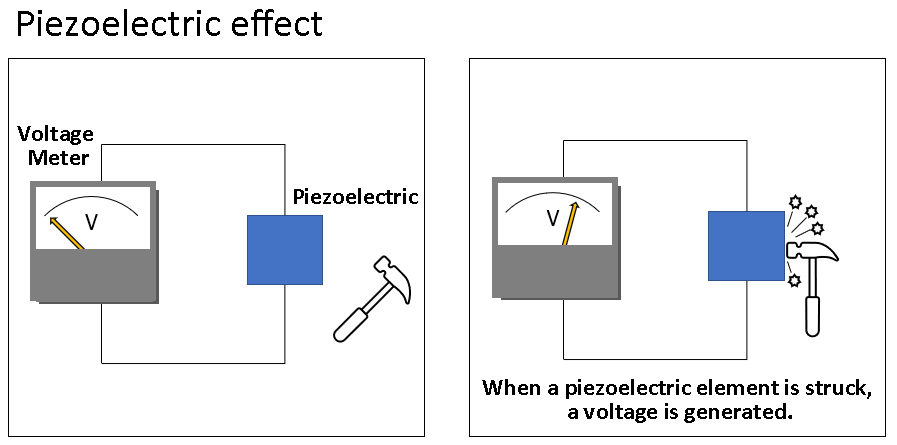

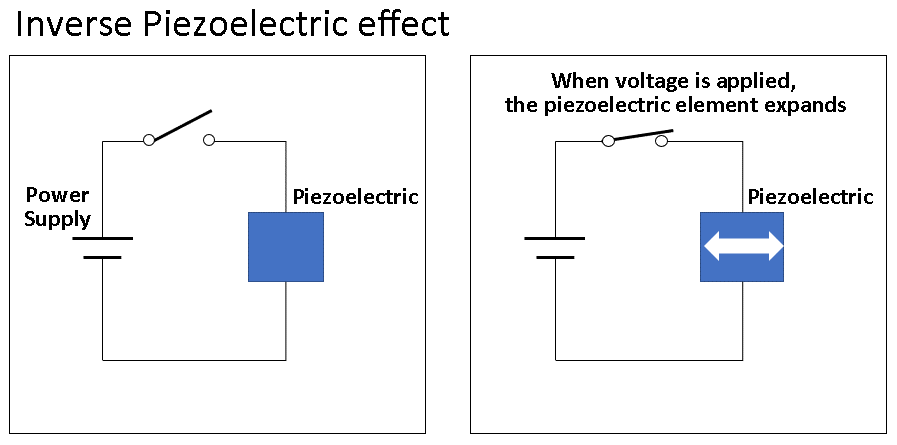

A piezoelectric element is an element that exhibits the "piezoelectric effect," which generates an electric charge or electric field when force is applied. Conversely, when a voltage is applied, it displaces and generates force (the inverse piezoelectric effect). In other words, the piezoelectric effect can be said to be a phenomenon in which kinetic energy (mechanical energy) is converted into electrical energy. The inverse piezoelectric effect is sometimes referred to collectively as the "piezoelectric effect."

The piezoelectric effect is also called the piezo effect, and the word "piezo" is said to be derived from the Greek word "piezein," which means "to push or compress."

The piezoelectric effect was discovered in 1880 by French physicist brothers Jacques and Pierre Curie. Pierre later won the Nobel Prize in Physics together with his wife. (Pierre's wife is Madame Curie, famous for being the first woman to win a Nobel Prize.)

Piezoelectric elements are commonly used in ignition devices such as lighters. When you press the switch, an internal part strikes the piezoelectric element, generating an electric spark that ignites gas or oil.

Initially, crystal (quartz) was used as a material for piezoelectric elements, but as research has progressed it has become possible to create more efficient materials, and now piezoelectric ceramics made by applying a high voltage to highly dielectric ceramics to create a polarization process are widely used.

The piezoelectric effect, which converts mechanical force or vibration into electricity, is widely used in acceleration sensors, force sensors, vibration gyro sensors, ultrasonic diagnostic equipment, etc. Research is also being conducted into power generation applications, such as floor power generation systems that light up LEDs when stepped on.

The inverse piezoelectric effect of piezoelectric elements (the effect of converting electricity into mechanical force) is used as the driving source for high-performance actuators (piezo actuators). Piezoelectric elements have excellent features such as high resolution, high-speed operation, small size, large generating force, and good energy efficiency.

Piezoelectric elements are used as the driving source of actuators in various forms. For example, they can be in a single plate form (single plate piezoelectric element) or a multi-layer form (multi-layer piezoelectric element). Unlike the single plate form, a multi-layer piezoelectric element is an element in which many internal electrodes are simultaneously fired inside the piezoelectric material so that it can be driven at a low voltage. By stacking the piezoelectric material in multiple layers, it is possible to overcome the drawback of the single plate form, which is its small displacement, and make it usable for some applications.

Characteristics of Piezoelectric Elements

While piezoelectric elements have excellent properties, they also have the following characteristics

① Small displacement

Piezoelectric elements expand smoothly in response to the applied voltage, but the expansion rate is about 0.1% of their length. For example, the displacement generated by a piezoelectric element with a length of 40 mm in the lamination direction is about 40 to 50 μm, which is less than the thickness of a single hair (average 50 μm to 80 μm). For this reason, the range of applications of piezoelectric elements is very limited. To compensate for this drawback of small displacement, we have developed a displacement magnification mechanism technology that uses the "principle of leverage" to magnify the displacement several to several tens of times. Our product, Mechatrans, is a piezo actuator that not only dramatically improves the smallness of the displacement by combining a piezoelectric

element with a displacement magnification mechanism, but also allows the displacement direction to be changed depending on the application.

② There is hysteresis

Piezoelectric elements have the property that the displacement path is different when the voltage is applied from zero to maximum voltage and when the voltage is applied from maximum to zero voltage. This is called "hysteresis (history phenomenon)". Therefore, even if the same voltage is applied, the displacement path is not the same, so it shows a different absolute position, resulting in a position error. The error is about 15% of the maximum displacement.

Piezo actuators use piezoelectric elements and therefore inherit the hysteresis characteristics. In other words, piezo actuators do not have the strict repeatability of moving to the exact same position when the same voltage is applied. However, by incorporating a sensor that measures the amount of displacement and using a control (closed-loop control) that feeds back the signal from the sensor and adjusts the applied voltage, it is possible to achieve stable

drive with high position repeatability. Closed-loop control allows for precise positioning in nanometer units.

Control that does not use feedback and only inputs the applied voltage is called open-loop control. Open-loop control is inferior to closed-loop control in terms of precision and repeatability of the operating position, but it can be constructed relatively easily and inexpensively.

Our positioning stage, called the "piezo-assisted stage*," can be used inexpensively with open-loop control, or it can be configured with closed-loop control using a PID control system to achieve stable, high-precision positioning in 15 nm increments.

③ Temperature characteristics and creep phenomenon

Piezoelectric elements expand and contract due to temperature changes. In addition, if a constant voltage is continuously applied, a creep phenomenon occurs in which the amount of displacement increases little by little. Open-loop control cannot correct such subtle positional deviations, but closed-loop control enables precise and stable control.

④ Vulnerable to high temperature and humidity

Piezoelectric elements can withstand a semi-permanent number of operations if used in an environment of room temperature and low humidity (40% or less), but if operated in a high temperature and high humidity environment (for example, 90% humidity), they may be damaged in just a few weeks. This only applies when driven under DC voltage conditions. Durability is slightly improved under frequently used ON (maximum voltage)/OFF (zero voltage) driving conditions.

We have over 20 years of design and usage know-how and can suggest appropriate designs, drive methods and usage methods, so please feel free to contact us with any questions.